Working papers are intended to make results of my ongoing research available to others and to encourage further discussion on the topic. Comments and clarification are welcome. This paper discusses creation of the Defense Acceptance Stamp (DAS) and its use on bayonets and scabbards.

The Defense Acceptance Stamp (DAS) was adopted pursuant to Department of Defense (DOD) Directive Number 4155.1, dated 20 October 1952. The directive was effective immediately, however, gave military departments until July 1, 1953, to implement.[1] This directive standardized inspection and acceptance stamps across DOD departments, replacing 39 different inspection and acceptance stamps (including the Ordnance Dept. shell-and-flame) with just two: a circular (partial) inspection stamp and a square (final) acceptance stamp.[2] The latter stamp is what collectors refer to as the DAS. The DAS was used on all manner of products procured by the DOD, not just ordnance items like rifles and bayonets.

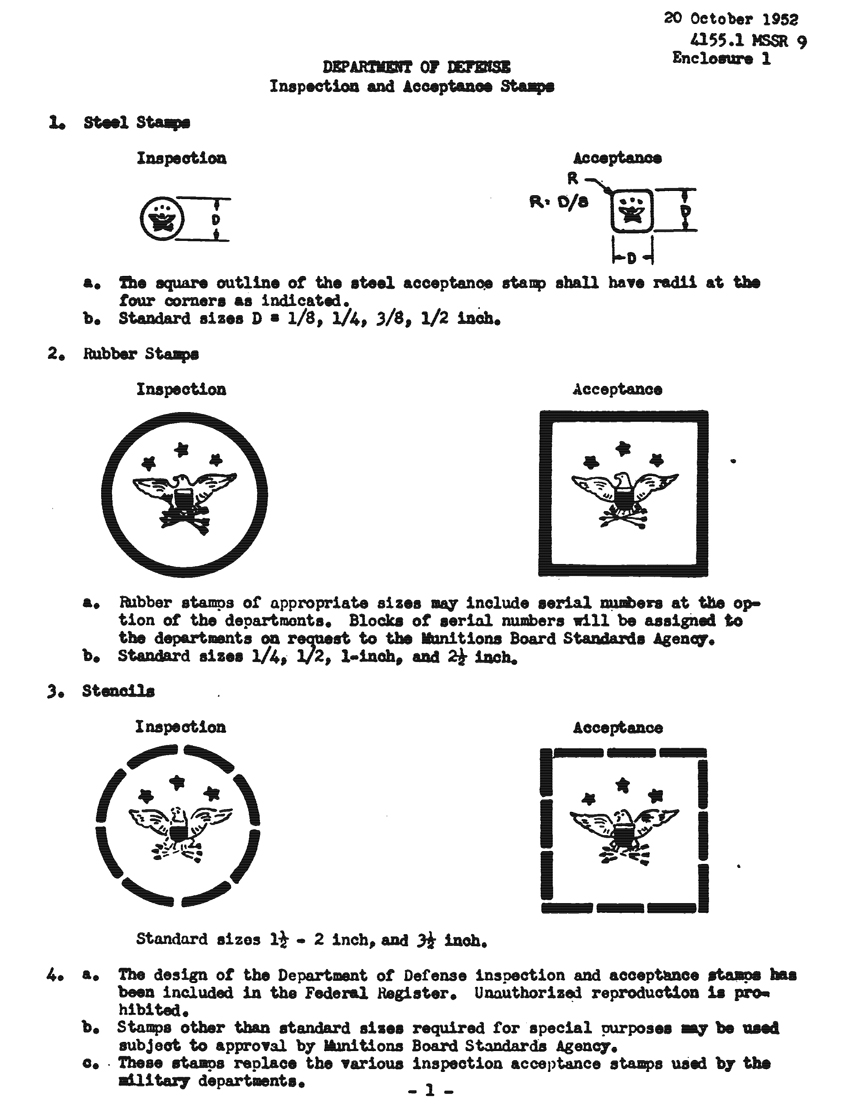

Authorized Stamps and Their Use

The DOD authorized three methods of applying the DAS: steel stamp, rubber stamp, and stencil. Steel stamps were used to impress the DAS into an item’s surface. Rubber stamps were used to mark with ink. Stencils were used to apply painted markings (e.g., on wooden shipping crates). Something allowed only with the larger rubber stamps was that a serial number could be incorporated at the military department’s request. [3] The original specifications for the authorized DAS stampers are shown below.

It is important to recognize that the purpose of the DAS was limited. The DAS was simply never intended to indelibly mark accepted items for all to see into perpetuity. The DAS was one of several “inspection aids” available to enable inspectors to control product during processing and to indicate inspection status.[4] By 1956 (and possibly earlier), Ordnance Department regulations explicitly state that:

“When a DOD procurement inspection approval stamp is affixed to any materiel, it shall not be construed to mean that the materiel has or has not been accepted by the government.”

DOD regulations also gave government inspectors significant discretion around its use, stating that:

“The stamping of each individual item is neither required nor prohibited. Ordinarily, the stamping of shipping containers, shipping documents, or lot routing tickets adequately serves to provide the necessary indication of inspection status and to control or facilitate the movement of material. Approval stamp markings will be minimized by using such markings only when it is necessary to establish local positive control of material.”[5]

These same rules, albeit somewhat abbreviated, remain in effect to the present day.[6] This provides room for apparent inconsistencies found in use of the DAS on bayonets and scabbards.

Analysis of Observations

The following analysis places observations of the DAS on bayonets and scabbards in context with relevant DOD policies and manufacturing history. Observations draw from my own research and previous work by noted authors/researchers, Gary Cunningham, Bill Porter, and Frank Trzaska; as well as from the broader the U.S. Militaria Forum community. Gary’s research can be found in his books; and the work of all three on Frank Trzaska’s great site, http://usmilitaryknives.com.

The DAS seems to have been used on bayonets more regularly during the 1950s and early 1960s. Thereafter, use of the DAS on bayonets appears more varied and sporadic, dying out completely ca. 1970. Defense procurement was reorganized and centralized beginning in 1962 under Secretary of Defense Robert McNamara. The Secretary’s push for efficiency and the subsequent increase of inspection workload during the Vietnam War likely influenced the mid-1960s reduction in use of the DAS on bayonets.[7] On scabbards, appearance of the DAS appears related to inspection practices in the two localities where manufacture of scabbard components is known to have occurred.

Sometimes, the DAS stamped into bayonets was lightly struck so could be faint, could wear away, or become obliterated during maintenance or refinishing. When applied to hard, non-porous surfaces such as bayonets and scabbards, an ink stamp is soon obliterated during use. For these reasons, the presence or absence of a DAS should not be criteria for determining whether a bayonet or scabbard is U.S. Government Issue (USGI).

With respect to bayonets, the most common practice appears to be marking on the crosspiece using a 1/8-inch or 1/4-inch steel stamp. Generally speaking, the following manufacturers’ bayonets were observed marked with the steel stamp DAS on the crosspiece:

- Aerial Cutlery Co., Marinette, Wisconsin: M5, M5A1 (marked M5-1), M6

- Columbus Milpar & Manufacturing Co., Columbus, Ohio: M5A1 (a few marked, but most not), M6 (some, but not all)

- General Cutlery Co., Fremont, Ohio: M1917

- Imperial Knife Co., Providence, Rhode Island: M4 (Post-War); M5, M5A1 (some, but not all), M6 (some, but not all)

- J & D Tool Co., Stamford, Connecticut: M5, M5A1 (marked M5-1)

- Turner Manufacturing Co., Statesville, North Carolina: M4

In addition:

- Canadian Arsenals Ltd., Ontario, Canada: M1917 bayonets observed marked on the crosspiece face in white ink using a rubber stamp.

- Bauer Ordnance Corp., Warren, Michigan: M7 bayonets observed marked in black ink on the pasteboard carton containing the bayonet. This is the last documented use of the DAS on bayonets or scabbards, occurring into 1970.

With respect to scabbards, the practice observed is marking in black ink on the scabbard body using a 1/2-inch or serialized 1-inch rubber stamp. Why a serialized stamp was employed and identity of the inspectors are not known. This is the only use of the larger 1-inch ink stamp observed on bayonet-related items. Most often, the 1-inch DAS is observed placed vertically on the scabbard body. Occasionally, it is observed placed horizontally causing the serial number to not print.

Generally speaking, scabbards assembled during the 1960s using components manufactured in Massachusetts by Victory Plastics and Beckwith-Arden Inc. were observed with the DAS. Scabbards assembled using components manufactured in Philadelphia, PA, by Viz Manufacturing Co. were not. The following manufacturers’ scabbards were observed marked with the rubber stamp DAS on the scabbard body:

Victory Plastics Co., Hudson, Massachusetts—

M8A1 scabbards from the 1961 contract were marked on the scabbard body using a 1/2-inch rubber stamp. M1917 scabbards produced 1962–63 were marked on the body using a 1-inch serialized rubber stamp (s/n 12413).

Wilson-Duggar Co., Jasper, Alabama—

The DAS on M8A1 scabbards produced at Wilson-Duggar Co. in 1964 appears to be inherited from the source of the plastic scabbard bodies. Leftover plastic scabbard bodies from Victory Plastics were used to assemble some of the M8A1 scabbards at Wilson-Duggar Co. These scabbards, marked WD, were observed with the DAS identical to Victory Plastics’ scabbards. However, Wilson-Duggar Co. scabbards marked WD/VIZ were not observed with the DAS. These are believed to have been assembled using plastic scabbard bodies supplied by Viz Manufacturing Co.

Beckwith-Arden Inc., Watertown, Massachusetts—

M7 scabbards produced ca. 1966 were marked on the body with the DAS in black ink using a 1-inch serialized rubber stamp (s/n 11418). M1917 scabbards produced 1967–68 were similarly-marked.

[1] Department of Defense, Uniform Inspection and Acceptance Stamps Prescribed for Use by the Military Departments, DOD Directive 4155.1 (Washington DC, Department of Defense 1952), https://www.google.com/books/edition/Federal_Supply_Management_implementation/XRzmyQFErAUC?hl=en&gbpv=1&dq=defense+ acceptance+stamping+4155.1&pg=PA43&printsec=frontcover

[2] Hearings on Department of Defense Appropriations for 1954, 83rd Cong.183–84 (1953) (testimony of Adm. Joseph W. Fowler, Director, Defense Supply Management Agency), https://www.google.com/books/edition/Hearings/TkHfEP3T2mMC?hl=en&gbpv=1&dq=defense+acceptance+stamping+replaces+39+ stamps&pg=RA2-PA184&printsec=frontcover

[3] Department of Defense, Uniform Inspection and Acceptance Stamps Prescribed for Use by the Military Departments.

[4] Ordnance Corps, Ordnance Inspection Administrative Manual, Vol. 1, General Inspection Administrative Methods, ORDM-41-1, Vol. 1, (Washington DC: Ordnance Corps., 1960), pages 14-10 & 14-11, https://www.google.com/books/edition/Ordnance_Inspection_Administrative_Manua/vAUiAAAAMAAJ?hl=en&gbpv=1

[5] Office of the Secretary of Defense: Procurement Inspection Stamping, 21 Federal Register 769, February 3, 1956, https://archive.org/details/sim_federal-register-find_1956-02-03_21_23/page/768/mode/2up

[6] Government Contract Quality Assurance, 48 C.F.R. 246.472 (2022), https://www.law.cornell.edu/cfr/text/48/246.472

Inspection Stamping, Defense Federal Acquisition Regulation Supplement (DFARS) Procedures, Guidance, and Information (PGI) 246.472, https://www.acquisition.gov/dfarspgi/pgi-part-246-quality-assurance#DFARS_PGI_PGI_246.472

[7] Lawrence s. Kaplan, Ronald D. Landa, and Edward J. Drea, History of the Office of the Secretary of Defense Volume 5: The McNamara Ascendancy 1961-1965 (Washington, D.C., Historical Office, Office of the Secretary of Defense, 2006), 24–29, https://history.defense.gov/Portals/70/Documents/secretaryofdefense/OSDSeries_Vol5.pdf

© Ralph E. Cobb 2022 All Rights Reserved